Cause of the cold this week, I didn’t manage to do much. Where I’m working at the moment, there’s no heating, and you can feel the cold comin’ out of the ground. There are nicer days to work on an install.

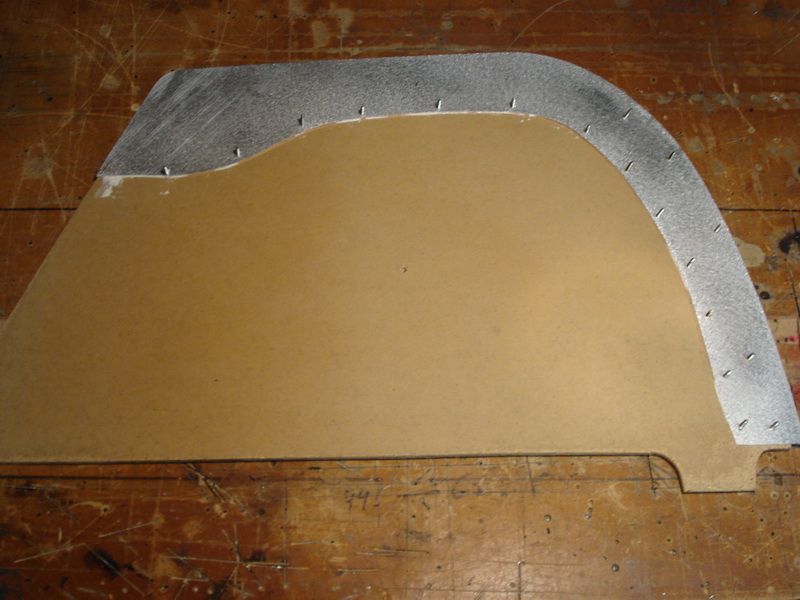

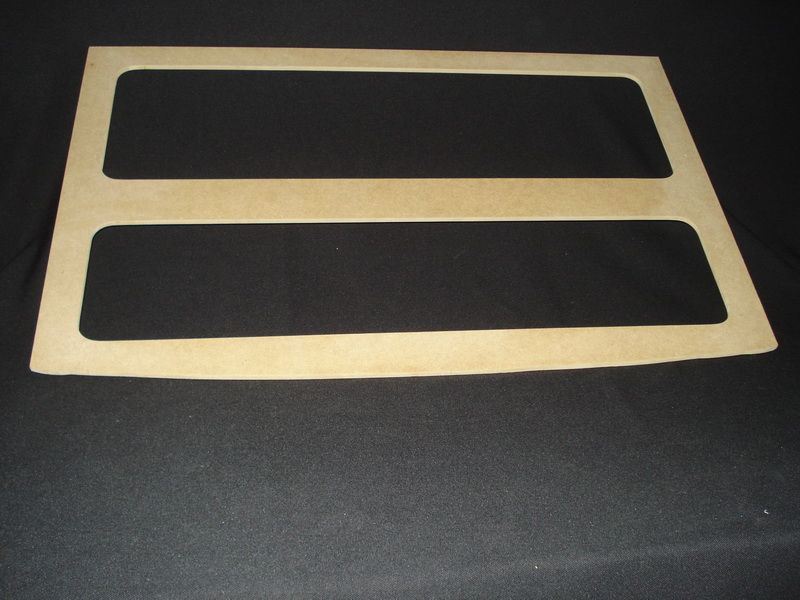

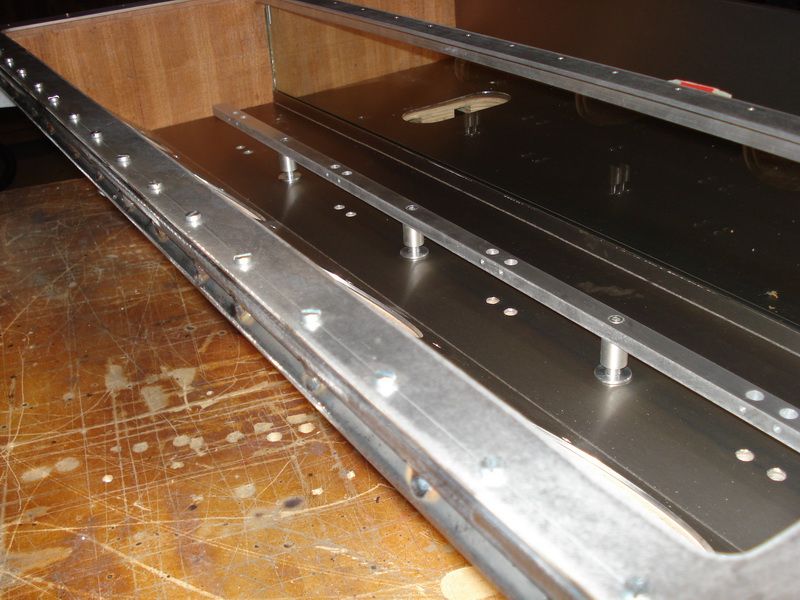

The 2 alu frames (for the glas to rest on) are finished. On the back of the subbox, where the hinge is placed, I had to weld an extra iron.

After that I drilled a LOOOOOOOOOOOOOOT of holes in the aluminium, and also in the iron and alu bar. After that I made some screw-thread in there so I could tighten it all nicely. Remember, the subbox needs to be 100% closed.

Once the holes were good, I taped the glass onto the aluminium.

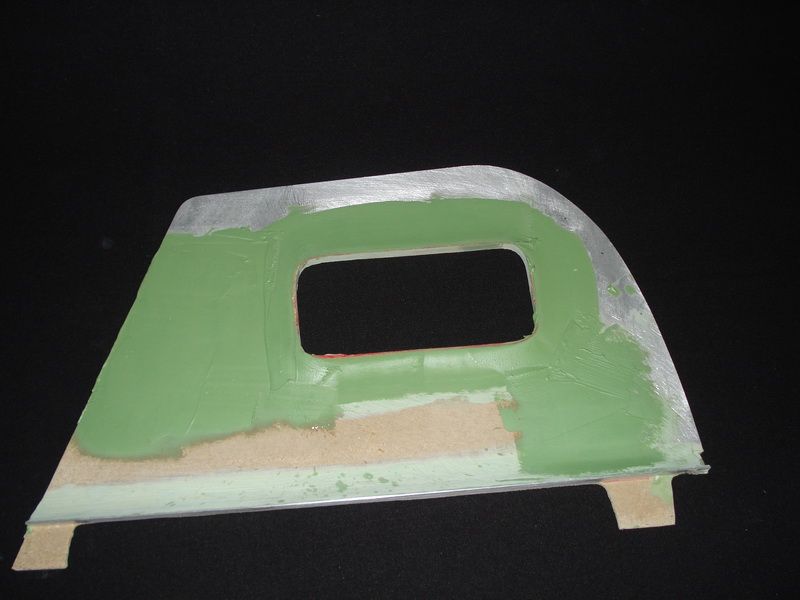

I chose 2x4mm laminated glass. This is the same as the glass that’s in your front windshield of your car. I chose this because it’s superstrong, be also, must it ever break, the shattered pieces won’t fall apart, due to the special film that’s in between.

You never know the glass will burst after my wife plants a bag of potatoes into the trunk, then it won’t be the end of the world… just needs a new glass.

I glued the glass with black TEK7.

I left this to dry for more than four days, and it still wasn’t dry. Probably because it’s cold and moist in my garage for the moment.

Then I worked on the connections of the woofers.

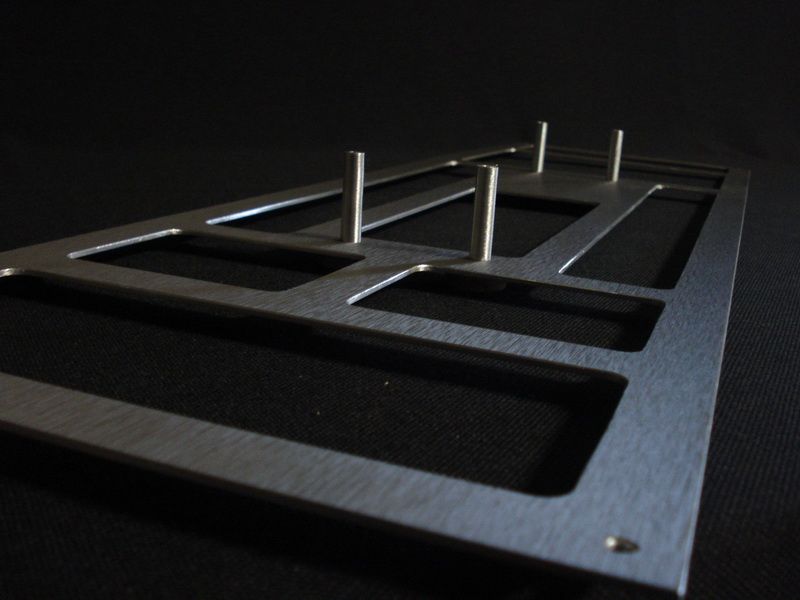

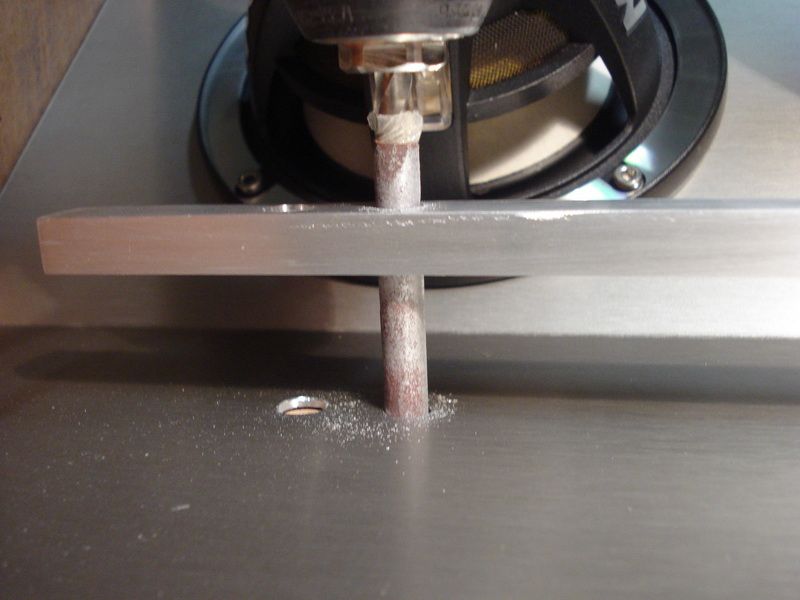

Here you can see the 8 alu tubes where the cable gets through. You can also see LED holders, and little O-rings.

First of all, I glued the led holders into the alu tubes with 2 components-glue

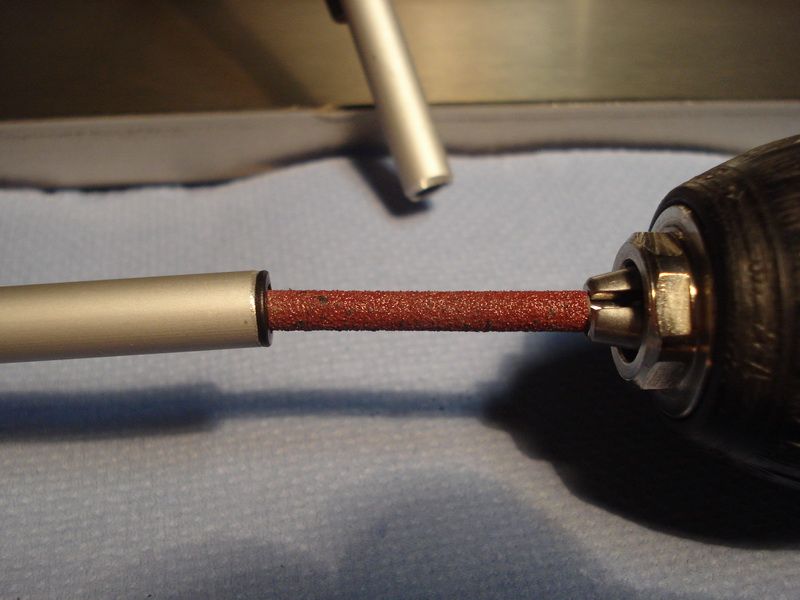

Because my cable didn’t got through anymore, I had to abrade the LED holders one by one till the cables got through again.

F*CKN JOB...

Another shitty job was that I had to sand down the inside of the holes, where the tubes glide through.

Once all this was done, I could place the tubes through the holes without scratching it.

You can also see the O-rings I slipped over it, to get a nice finishing touch.

With these connections I want to prove that it doesn’t always have to be copper, and you can make nice things with normal stuff.

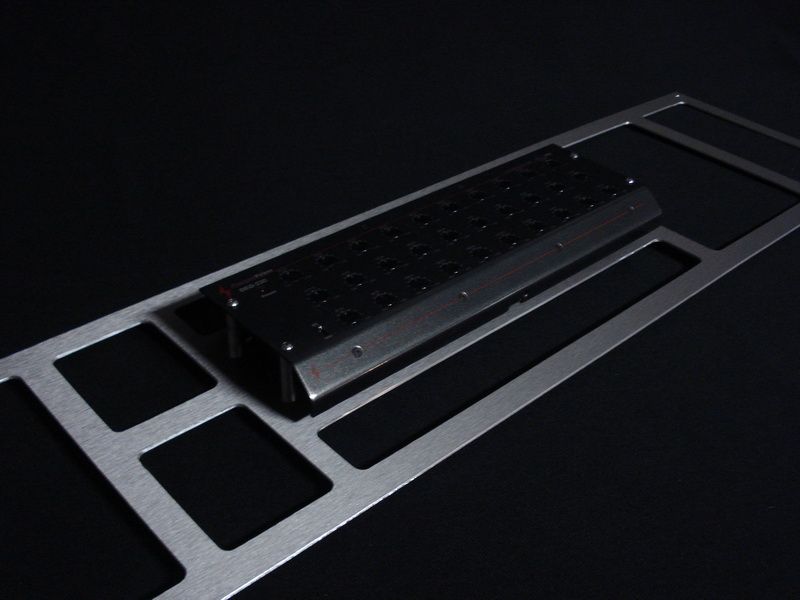

Here you see how the glass rests on the subbox, and how it’s screwed. Offcourse I’m going to place rubber in between to get a more perfect seal.

The glass on the amplifier part: This will be tightened with a couple of screws, so if I have to turn the EQ, it’s just a matter of screwing some screws loose.

Another cool shot